My Log Book for the Second Semester (SHP201)

August 21, 2012 Leave a comment

My Log Book for the Second Semester (SHP 201)

About My Log Book

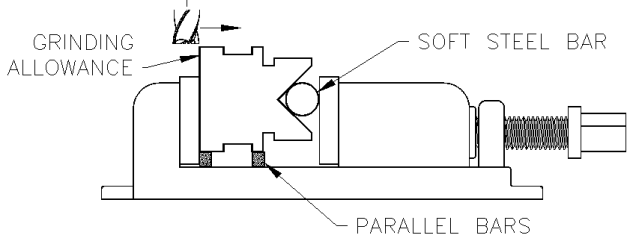

The main purpose of my logbook is to record my performance in detail, including manufacturing description and drawing in the machine shop. My professors review my logbook and give marks when one project is done. It is my responsibility to make sure my log book is kept up-to-date. I made hand drafted detail part drawings and hand printed operation sheets indicating how the part was made. Some students don’t take care of it, but I think it is important to prove conclusively my manufacturing ability to a future employer.

About SHP 201

This course builds on the marching skills introduced in SHP 101. Projects have been designed to broaden the students machining skills while allowing the participants to develop further machining techniques. Although the main thrust of this courses is metal cutting, a great deal of time is spent on developing effective plaining and time management skills.

Prerequisite for SHP 201 : Completion of SHP 101, good English language and comprehension skills, the ability to work with others as a team, and good time management skills

- Log Book